Internal links:

Other Languages:

The Technion LEAPCON™ (Technion Lean Apartment Construction) game simulates construction of an eight story building with four apartments on each floor. It was initially developed to test the impact of a Lean management model that was proposed in response to the significant waste identified in the conventional approach to scheduling and managing construction of high-rise residential buildings. It was found to be an excellent tool for introducing project managers, site engineers, supervisors, senior management, and students at all levels to some of the basic concepts of lean construction: single-piece vs. batch flow, pull vs. push scheduling and control, and multi-skilling vs. task specialization.

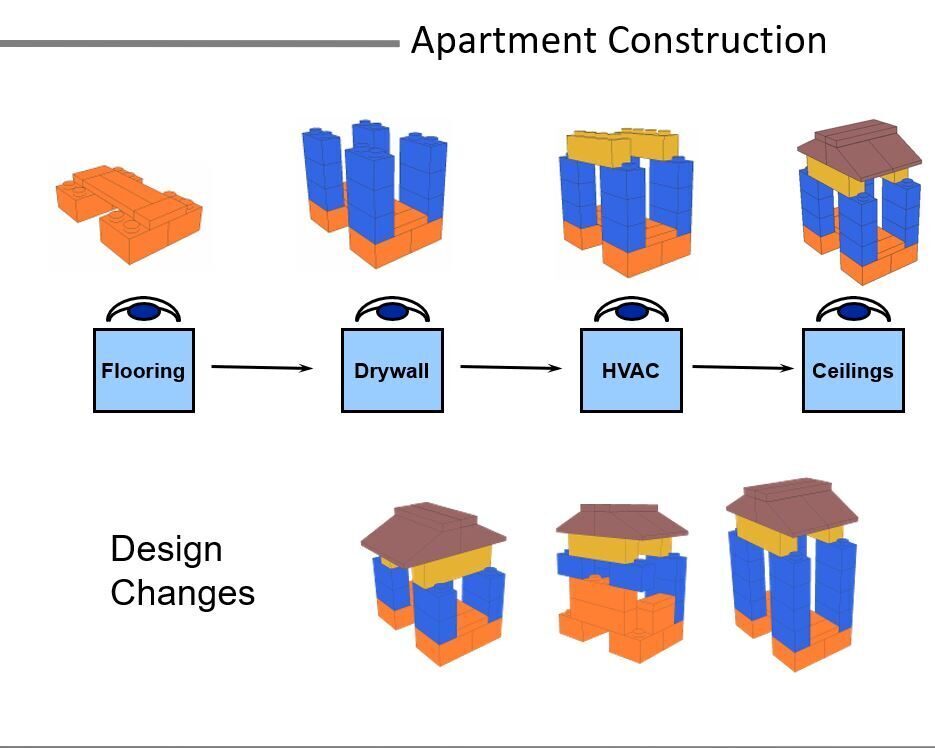

Participants are assigned the roles of project manager, a client change manager, a quality controller, a tower crane operator, and four specialty contractors. Their task is to carry out the interior finishing works for all 32 apartments in as short a time as possible. Execution of the finishing works is simulated using assembly of small building models using LEGO® bricks (see Figure 1); they are assembled in four distinct steps, each performed by one of the specialty contractors. Two additional players represent the apartment clients – the first selects design variations from a predefined set of seven variations to the basic design, and the second checks completed apartments and pays $1,500 each for those without defects.

Figure 1. A standard apartment. Assembly steps represent flooring (orange), partitions (blue), electrical wiring (yellow) and acoustic ceilings (brown).

Figure 1. A standard apartment. Assembly steps represent flooring (orange), partitions (blue), electrical wiring (yellow) and acoustic ceilings (brown).

In the first round of play, which lasts 11 minutes, the project manager is provided with a suggested construction plan which calls for the specialty contractors to progress up the building floor by floor, one after the other, in logical sequence according to the technological dependences of their work type. The batch size is four – only one contractor may work on a floor at a time. At set time intervals during construction, the clients select design variations by pulling apartment numbers and variation codes at random from a hat and deliver them to the ‘company’. Design variations received before work on an apartment is commenced are easily executed, although they do disrupt steady flow because they require more time. Apartments for which design variations are received after work has begun but before the apartment has been delivered to the client, must be changed. The project manager must decide whether to withdraw specialty contractors from the floors they are working on and send them to make local changes, or to delay the changes. The driving factor is that the company is only paid for completed apartments, while they must invest working capital ($1,000) for any incomplete apartment. Play is stopped after 11 minutes, and the team’s performance is assessed in terms of apartments delivered, quantity of WIP, cash flow, defective apartments, and the time required to deliver the first non-standard apartment. The results measured through distinct executions of the game with seven different groups are provided in Table 1 below.

In the second round, the following changes are made:

1. Pull scheduling replaces push scheduling – the work sequence is changed to match the sequence in which design variations are selected be pulled by the clients’ selections of design variations (work is only begun on apartments once the design variations are selected),

2. The four specialty contractors are replaced with four multi-skilled apartment finishing teams that can perform all of the activity types.

3. The batch size is reduced from four to one.

All other conditions remain as before. Typical results for this round, obtained by the same seven groups, are listed in Table 4. As can be seen, productivity is approximately doubled, WIP is drastically reduced (as in all pull systems, it is explicitly controlled) as is cycle time, and as a result, cash flow turns from negative to positive.

Table 1. Average results, 11 repetitions.

| Conventional management | Lean management | |

| Apartments Completed | 8.0 | 15.6 |

| Defective Apartments | 0.57 | 0.00 |

| Time to First Apartment (min.) | 06:35 | 02:49 |

| W.I.P. | 13.4 | 2.3 |

| Throughput (units/min) | 1.12 | 2.3 |

| Cash Flow | ($9,429) | $5,500 |

| Cycle Time (min.) | 06:00 | 01:21 |

Some of the leading lights of lean construction playing the Technion LEAPCON™ game (from left to right; Tariq Abdelhamid, Carlos Formoso, Fritz Gehbauer, Ken Walsh, Lauri Koskela, Glenn Ballard)

How to obtain the game

The Technion LEAPCON™ game is available free of charge for academic use in a university, or for a small fee for commercial use. The package includes complete step by step instructions for each role, playing cards, ordering list for Lego® bricks, and directions for facilitators. To obtain the game, please e-mail Dr. Rafael Sacks.

The game is available in English, Russian and Spanish versions.

Bibliography

- Sacks, R., and Goldin, M., (2007). ‘Lean Management Model for Construction of High-rise Apartment Buildings’, ASCE Journal of Construction Engineering and Management, Vol. 133 No. 5 pp. 374-384.

- Sacks, R., Esquenazi, A., and Goldin, M., (2007). “Simulation of Lean Construction Management of High-rise Apartment Buildings”, ASCE Journal of Construction Engineering and Management, Vol. 133 No. 7 pp. 529-539.

- Sacks, R., Goldin, M., and Derin, Z. (2005). ‘Pull-driven construction of high-rise apartment buildings’ Proceedings of the 13th Conference of the International Group for Lean Construction, R. Kenley (Ed.), Sydney, Australia, pp. 217-226.

- Esquenazi, A., and Sacks, R., (2006). ‘Evaluation of Lean Improvements in Residential Construction using Computer Simulation’, Understanding and Managing the Construction Process: Theory and Practice, Proceedings of the 14th Conference of the International Group for Lean Construction, R. Sacks and S. Bertelsen, (Eds.), Santiago, Chile, pp.137-149.

- Sacks, R., and Derin, Z., (2006). ”WORKMANAGER’ – an Online Interface for Lean Flow Control in Apartment Building Construction’, ICCCBE-XI – 11th Int’l Conference on Computing in Civil and Building Engineering, H. Rivard and E. Miresco, (Eds.), Montreal, Canada, pp. 1176-1185.

Frequently Asked Questions

- I have a query on the game related to the CONVENTIONAL ROUNDFor example, if an apartment is being built to a the Standard Design (A) and the flooring, partition and the HVAC duct work has been completed. After this completion design change calls for Design (F) ie. Partition has to be changed/ Ceiling is rotated 90 degree. What is the correct procedure?

- a) Will the partition contractor come and he will remove the duct and then modify the partition. After that reassemble the duct, OR

- b) First ask the duct sub contractor to dismantle the duct, then the partition contractor to modify the partition and then the duct contractor again to refix the dismantled duct.

What is your advice in playing in such a situation.

Rajiv Misra, XLRI, India

Strictly speaking, solution b) is the correct one. However, we are all human, and I have found that when the pressure is on, and the players feel that they are trying to compete with the clock, then sometimes they have trouble sticking to this rule, and they act as you described in a).

I have found that it makes only a small difference; but I have always made a point to explain to them in the summary discussion after the conventional round that exactly that kind of situation arises in real buildings. What happens then is that either the partitioning subcontractor says ‘Hey, it’s not my job to undo the ductwork!!’ and the project is delayed, or the project manager insists that they do undo the ductwork to avoid delay, and then damage night be done. Either way, it reinforces the participants understanding of how specialization of tasks in construction has such a detrimental effect on flow when changes are common.

- Quick question — what would you say is the minimum time to play the game ? I have 1h15m in my class.Bill O’Brien, Texas A&M, USAAbout 1h45m has been the minimum time when running the game in a single session, although the smaller the group the quicker it can be set up and run – it depends a lot on how much explanation and background you need to provide them on lean production/construction before you begin the game itself.For a 1h15min session, I recommend splitting it into two. During the first session, you could provide background, explain the setup, and run the first round comfortably. Then, in a following session, you would need about 45m to do the second round and to debrief them. You could even pose a ‘homework’ challenge after the first session that the students should try to come up with an alternative management scheme and submit it before they actually are told the rules of the second round and do it. I have considered at times whether to allow an intermediate round in which the students design a system and then implement it, before showing them the benefits of pull flow, single piece flow and multi-skilling; that is something you could implement at the start of a second session.

- I have seen in one of the videos (The Tidhar way http://youtu.be/2gGgCL4ZQUo ) that “The team decided to let go of the project manager and hire a second quality assurance”. In addition to this, I see that every player has a stacked amount of pieces in front of him. Did they prepare the “stock” before?Filippo Bossi, Università degli Studi di Firenze – Department of Architecture The Tidhar group had run the game a number of times, and they were trying to perfect it. They were free, in this third round, to reassign tasks within the contracting company, with one condition: they were not allowed to increase the number of production workers. Only four are allowed, the same in all rounds. They identified that the project manager was under-employed in the second round, so they assigned him to help with the quality control. Most groups do not think of this the first time they play the second round, but if you have time and you decide to play a third round, then you can challenge them to think of further improvements such as this.The tower crane and the material transport are not the main focus of the game, and so I usually do not object, if there ius a third round, that they pre-prepare piles of material close to the work place.

LEAPCON users

| Country | Educational | Industrial or Governmental |

|---|---|---|

|

| |

|

| |

|

|

|

|

| |

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

| |

|

| |

|

| |

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

| |

|

| |

|

|

|

|

| |

|

| |

|

|

|

|

|

|

|

| |

|

|

|

|

Resources